In modern manufacturing, success often hinges on the harmony between tooling design and production. When these elements work together, efficiency soars and product quality rises. Achieving integration requires thoughtful planning, clear communication, and a shared vision for improvement.

The Importance of Early Collaboration

Engineers utilize professional tooling design services support for improved manufacturability. Early collaboration brings tooling engineers and production teams in sync. Communicating together enables the identification of potential issues before they become costly nuisances. Early collaboration shapes designs for practical manufacturing. This type of discussion establishes the foundation for a simplified workflow and fewer obstacles. Engaging both sides at the start tends to minimize mistakes and results in better output.

Design for Manufacturability

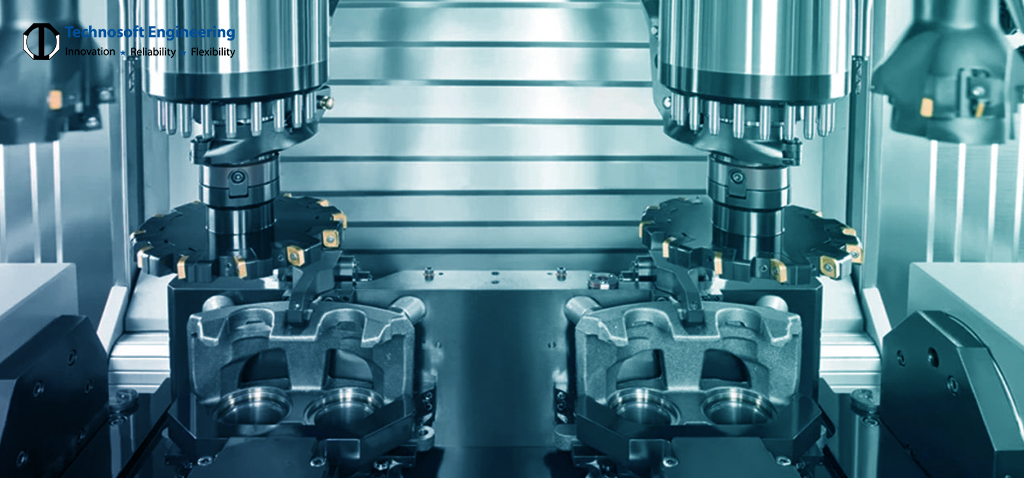

Manufacturability is the most crucial aspect of creating tools tailored for production processes. Designers need to take into account the equipment they have available. By aligning tool functionality with the producibility of the tool features, we can simplify assembly and reduce scrap. Less complex tool geometries can reduce the time and cost of producing them. Designers mitigate this risk by factoring manufacturability into the design, ensuring that tools mesh with existing operations.

Communication Bridges the Gap

Frequent communication between design and production teams mitigates misinterpretation. Regular meetings help relay updates and challenges among all parties. Periodic updates on what is going well and what is not keep both sides on the same page. Having an open dialogue process will build trust and speed up the solution. Digitally mediated communication tools bolster this link and enable the provision of instant feedback.

Feedback Loops Drive Improvements

Feedback from the people who actually use the tools further shapes the tool’s design. Sometimes, operators spot issues that might have gone unnoticed in the initial design reviews. Designers can polish their tools this way with the help of shared observations. They develop feedback loops, which reduce friction in progress and enable more efficient performance in the long run.

Technology Enhances Coordination

Using digital tools helps in bringing together design and production. Virtual testing of tools can be done via simulation software before they are even manufactured. To visualize how designs will behave on the shop floor, digital twins can benefit teams. Cloud platforms allow you to share your files and the changes you have made right away. These technologies enhance collaboration and expedite the process of necessary changes.

Training Supports Smooth Transitions

The new tooling needs to be trained throughout production. Ready teams respond fast to changing equipment and processes. Conduct training sessions on tool usage, maintenance, and troubleshooting. Providing employees with ways to practice with new systems gives them confidence. Educating staff ensures that as designs change over time, people will be up-to-date on what to do with them.

Quality Assurance Links Both Sides

Design and production are two distinct phases and require quality inspection in between. Final product standards are protected by inspecting tools for accuracy and reliability. Scheduled audits identify variances before they impact output. When teams jointly review each other’s work, it reinforces accountability and fosters a joint dedication to quality. QA aligns designers and operators on the objective of delivering better outcomes.

Monitoring and Measuring Outcomes

Tracking performance after integration is vital for continued progress. Measuring factors like cycle time, defect rates, and tool wear reveals the impact of design choices. This data supports objective decision-making for future improvements. Regular analysis helps identify patterns that may indicate more profound issues. Monitoring outcomes ensures that integration efforts deliver lasting value.

Continuous Improvement as a Principle

Continuous improvement is the lifeblood of successful integration. Designers and producers should constantly strive to reduce the time it takes to get work done. These small data-driven changes can compound and lead to big wins in the long run! Promoting a culture of learning ensures that all are forced to stay engaged and will want to be invested in collective victory. It makes integration an ongoing journey rather than a one-time event.

Conclusion

Integrating tooling design with production delivers measurable benefits for manufacturers. Early collaboration, strong communication, and constant feedback lay the groundwork for success. Embracing technology, standardization, and training further strengthens this connection. By working together, teams create a cycle of improvement that drives productivity and quality to new heights.