Original Equipment Manufacturers (OEMs) rely on precision, reliability, and efficiency in every stage of production. Their success depends on sourcing components that meet tight tolerances and deliver consistent quality at scale. With growing pressure to cut costs while maintaining excellence, the manufacturing process plays a decisive role in long-term competitiveness.

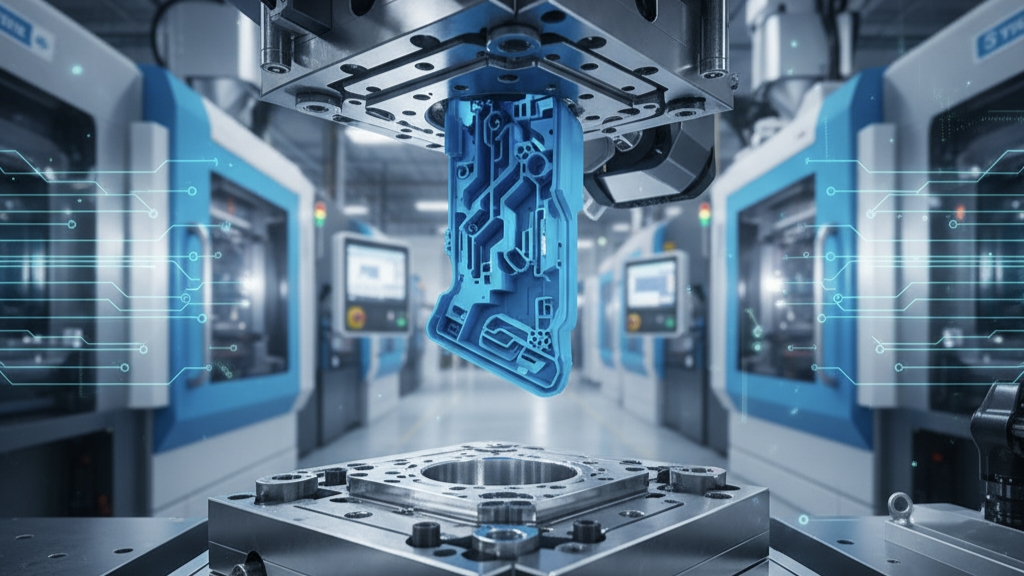

Many OEMs now choose custom plastic injection molding as their preferred method for producing complex parts and assemblies. This approach combines flexibility with cost control, allowing companies to design parts tailored to their unique applications. The result is improved product performance, faster production cycles, and stronger brand consistency across markets.

Precision and Consistency in Every Part

OEMs value predictability in production. Custom plastic injection molding allows them to achieve precise dimensions and repeatability across thousands or even millions of units. Each part meets exact standards for shape, weight, and surface finish. This accuracy helps reduce assembly errors and improves the reliability of the final product.

Consistency also ensures smoother collaboration with suppliers and downstream partners. When each part fits perfectly, manufacturers avoid rework and delays, keeping production schedules steady. This is especially critical in industries like automotive, electronics, and healthcare, where quality deviations can lead to significant losses.

Cost Efficiency and Material Utilization

Production cost control remains a top priority for OEMs. Injection molding minimizes waste by using exact material volumes for each cycle. The molds are engineered to optimize flow and reduce excess, which directly lowers expenses without compromising quality.

Another benefit is the wide selection of resins available. Engineers can choose materials that balance performance with cost efficiency. With advanced molding techniques, parts can incorporate multiple functions, eliminating the need for separate components and further cutting assembly costs.

Design Flexibility and Product Innovation

OEMs are always searching for new ways to enhance performance and aesthetics. Injection molding gives design teams the freedom to create intricate shapes and fine details that other methods can’t easily achieve. Engineers can experiment with surface textures, thickness variations, and color combinations to suit brand requirements.

Prototypes are also easier to refine. Rapid tooling allows quick adjustments before full-scale production begins, helping teams bring innovative products to market faster. This flexibility supports industries that rely on constant product evolution, such as consumer electronics or medical devices.

Durability and Structural Integrity

A well-designed injection-molded part combines strength and stability. The process ensures even material distribution, preventing weak points that could compromise performance. OEMs can produce lightweight parts that still meet demanding strength standards.

Durable components extend product lifespan and enhance brand reputation. Even when used in industrial machinery or consumer appliances, parts produced through this method stand up to repeated use and environmental stress. This reliability helps OEMs maintain warranty standards and reduce post-production costs.

Streamlined Production and Scalability

Custom plastic injection molding supports efficient scaling, making it ideal for both short and long production runs. Once a mold is created, it can produce identical parts continuously with minimal downtime. The automation involved also reduces labor dependency, improving output consistency.

This scalability makes it easier for OEMs to respond to market fluctuations. When demand increases, production can ramp up without major process adjustments. Conversely, smaller runs can be handled efficiently, allowing flexibility across multiple product lines.

Compatibility with Advanced Manufacturing Technologies

Modern injection molding integrates easily with digital manufacturing systems. Many OEMs now use computer-aided design (CAD) and simulation tools to optimize mold performance before production starts. This digital precision minimizes risk and shortens development cycles.

The process also complements automation and robotics. Robotic part handling reduces cycle time and improves safety in production environments. These technologies align with lean manufacturing principles that many OEMs follow to maintain competitiveness.

Sustainability and Resource Efficiency

Environmental responsibility has become a key factor in manufacturing strategy. Injection molding supports sustainable practices by enabling the use of recyclable resins and reducing raw material waste. Some facilities even reclaim scrap materials for reuse in future runs.

Energy-efficient equipment and optimized cooling systems further reduce production footprints. For OEMs with sustainability goals, adopting this method strengthens environmental credibility while maintaining operational efficiency. It’s a balance of performance and responsibility that appeals to both manufacturers and consumers.

Better Supplier Partnerships

OEMs rarely manage injection molding in isolation. They collaborate with specialized partners who bring expertise in mold design, material selection, and quality assurance. A reliable supplier relationship ensures smoother transitions between design, prototyping, and mass production.

Experienced partners also help identify improvements that enhance durability and efficiency. By aligning with experts in custom plastic injection molding, OEMs gain access to innovation without adding internal complexity. This partnership-driven model keeps them agile in a fast-moving industrial landscape.

Precision, scalability, and reliability make custom injection molding the clear choice for modern OEMs. The method provides cost control, design freedom, and durability while aligning with digital and sustainable manufacturing trends. Custom plastic injection molding has evolved into a strategic asset that supports innovation and efficiency across global supply chains. For OEMs focused on long-term success, this process remains essential for building products that stand the test of time.