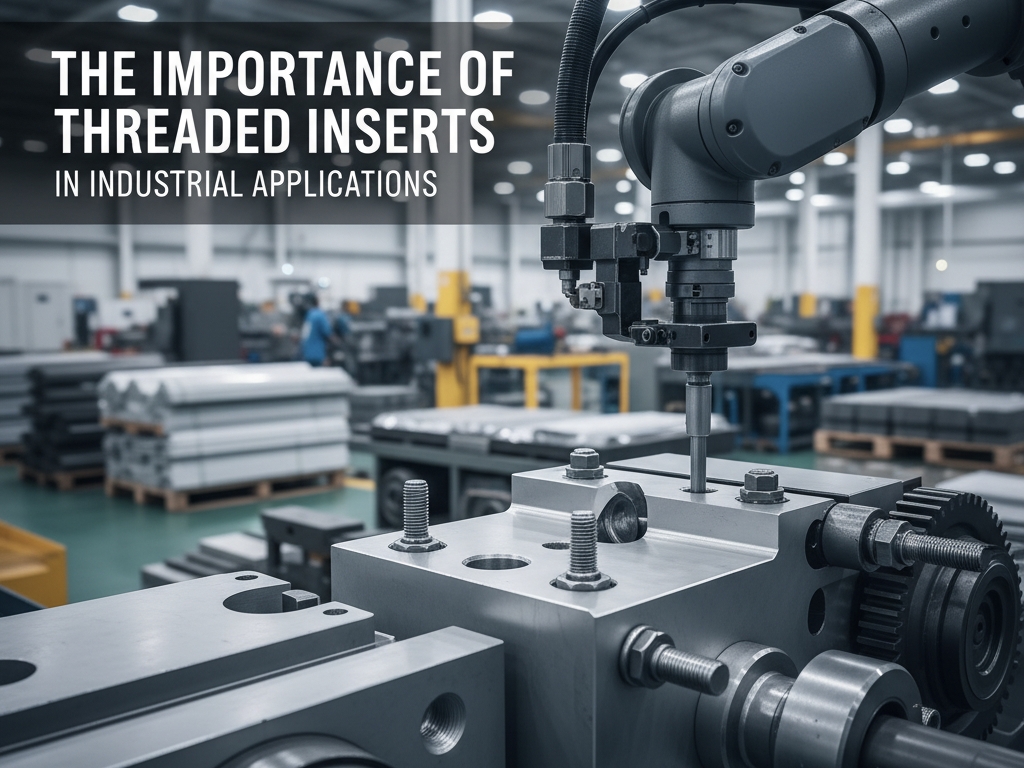

In the world of industrial manufacturing and production, precision and durability are paramount. Components that allow for repeatable and reliable assembly, such as threaded inserts, play a critical role in achieving these goals. They are essential in applications that require frequent assembly and disassembly, as they provide strong, reusable threads.

What are Threaded Inserts?

Threaded inserts are cylindrical metal components designed to be inserted into a pre-drilled hole in a material. They provide a reliable and reusable thread that allows for the secure fastening of components. Available in a variety of materials, threaded inserts are used in numerous applications, from electronics to heavy machinery.

Benefits of Using Threaded Inserts

The use of threaded inserts offers invaluable benefits, particularly in terms of improving the longevity and mechanical performance of a product. They enhance the wear resistance of threads by providing a stronger threaded connection than the base material alone, which is especially crucial in soft materials like wood and plastic.

Improved Load Distribution

One of the significant advantages of threaded inserts is their ability to distribute the load evenly across the fastened joint. This improved load distribution minimises stress concentrations, thereby reducing the risk of material failure.

Ease of Maintenance

Threaded inserts facilitate easier maintenance and repair processes. Components can be disassembled and reassembled without compromising the integrity of the original mounting hole, which is essential in maintenance-intensive environments.

Types of Threaded Inserts

There are several types of threaded inserts available, each designed for specific applications. Common types include helical wire inserts, solid body inserts, and self-tapping inserts. Each type serves a unique purpose and offers distinct advantages.

Helical Wire Inserts

Helical wire inserts, often made from wire wound into a helical coil, are particularly beneficial in applications requiring high resistance to wear and galling. They are ideal for situations where restoring damaged threads is necessary.

Solid Body Inserts

Solid body inserts are typically used in applications where high strength and durability are required. They are appropriate for both metallic and non-metallic materials.

Self-Tapping Inserts

Self-tapping inserts, also known as self-threading inserts, are designed to cut their own threads as they are installed. This feature makes them exceptionally useful in applications where pre-tapped holes are not feasible.

Applications of Threaded Inserts

Threaded inserts find application in a wide range of industries. In the aerospace sector, they are used to enhance the reliability of fastening components in aircraft. In the automotive industry, they help in assembling parts that must withstand frequent vibrations. Additionally, they are extensively used in consumer electronics where compact, reliable fastenings are necessary.

Material Considerations

Choosing the right material for threaded inserts is crucial. Common materials include steel, brass, and stainless steel. Steel inserts offer high strength, brass provides excellent corrosion resistance, and stainless steel is ideal for applications requiring high corrosion resistance and aesthetic appeal.

Installation of Threaded Inserts

The installation of threaded inserts involves drilling a hole to accommodate the insert, which is then driven or pressed into place. The right tooling and method are critical to ensure the insert’s performance and longevity.

Conclusion

Threaded inserts are indispensable components that enhance the functionality and durability of assemblies in various industries. As technology advances, the continual development of threaded insert designs will offer even greater efficiencies and benefits in industrial applications.