In the modern industrial landscape, where efficiency and precision are paramount, CNC machinery emerges as a game-changer. From automotive to aerospace, CNC machines are revolutionizing manufacturing processes with unparalleled accuracy and speed. For those eager to explore the intricacies of this technology, this blog provides an in-depth look into the world of CNC machinery, its applications, and its benefits.

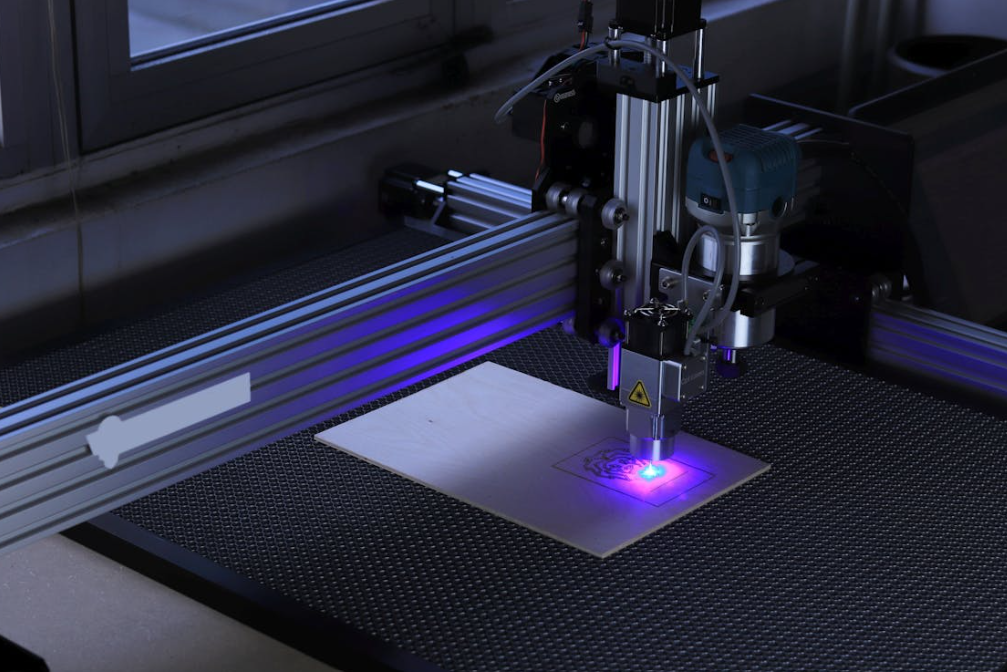

What is CNC Machinery?

CNC, or Computer Numerical Control, machinery refers to automated milling devices controlled by software programs. Unlike traditional machines operated manually, CNC machines follow coded instructions to perform intricate cutting, drilling, and milling tasks with high precision.

The Evolution of CNC Technology

The advent of CNC technology dates back to the mid-20th century, transforming manufacturing forever. Early machines relied on punched tape for programming, but today’s CNC machines leverage advanced software for enhanced functionality. The evolution continues, with innovations like AI and IoT integration pushing the boundaries of what’s possible.

Types of CNC Machines

CNC machines come in various types, each designed for specific tasks. Common types include CNC mills, lathes, and routers. CNC mills are ideal for complex shapes, while lathes are perfect for cylindrical parts. Routers, on the other hand, excel in cutting and carving materials like wood and plastic. For more information, contact a company such as Quickturn Pty Ltd.

Key Components of CNC Machinery

Understanding the components of CNC machinery is essential for grasping its functionality. The primary elements include the controller, spindle, and bed. The controller acts as the brain, decoding and executing instructions. The spindle holds and rotates the cutting tool, while the bed provides the workspace.

Programming CNC Machines

Programming CNC machines involves creating a set of instructions for the machine to follow. This is typically done using G-code, a standardized language for CNC programming. Mastering G-code allows operators to create detailed and precise instructions, ensuring optimal machine performance.

Benefits of CNC Machinery

The benefits of CNC machinery are manifold. Precision is perhaps the most significant advantage, as CNC machines can produce parts within tight tolerances. Additionally, automation reduces human error, increases efficiency, and allows for complex designs that would be impossible with manual machining.

CNC Machinery in Different Industries

The versatility of CNC machinery makes it invaluable across various industries. In automotive manufacturing, CNC machines are used to produce engine components and body parts. The aerospace sector relies on CNC for high-precision parts, while the medical industry uses CNC technology to create implants and surgical instruments.

Maintenance and Troubleshooting

Regular maintenance is crucial for the longevity and performance of CNC machinery. Routine checks and lubrication prevent wear and tear, while troubleshooting common issues like tool breakage and alignment errors ensures uninterrupted operation. A proactive approach to maintenance can significantly extend the lifespan of CNC machines.

Implementing CNC Machinery in Your Business

Implementing CNC machinery requires careful planning and consideration. Factors such as the specific needs of your business, budget, and available space must be evaluated. Partnering with reputable CNC machinery suppliers and investing in operator training can also facilitate a smooth transition.

Conclusion

CNC machinery represents the pinnacle of manufacturing precision and efficiency. Understanding its components, benefits, and applications can empower businesses to leverage this technology for optimal results. By staying informed about future trends and maintaining a proactive approach to maintenance, companies can harness the full potential of CNC machinery. To explore more about CNC technology and its applications, consider reaching out to industry experts or conducting further research. The precision and efficiency offered by CNC machinery can significantly elevate your manufacturing capabilities, ensuring you stay ahead in the competitive industrial landscape.