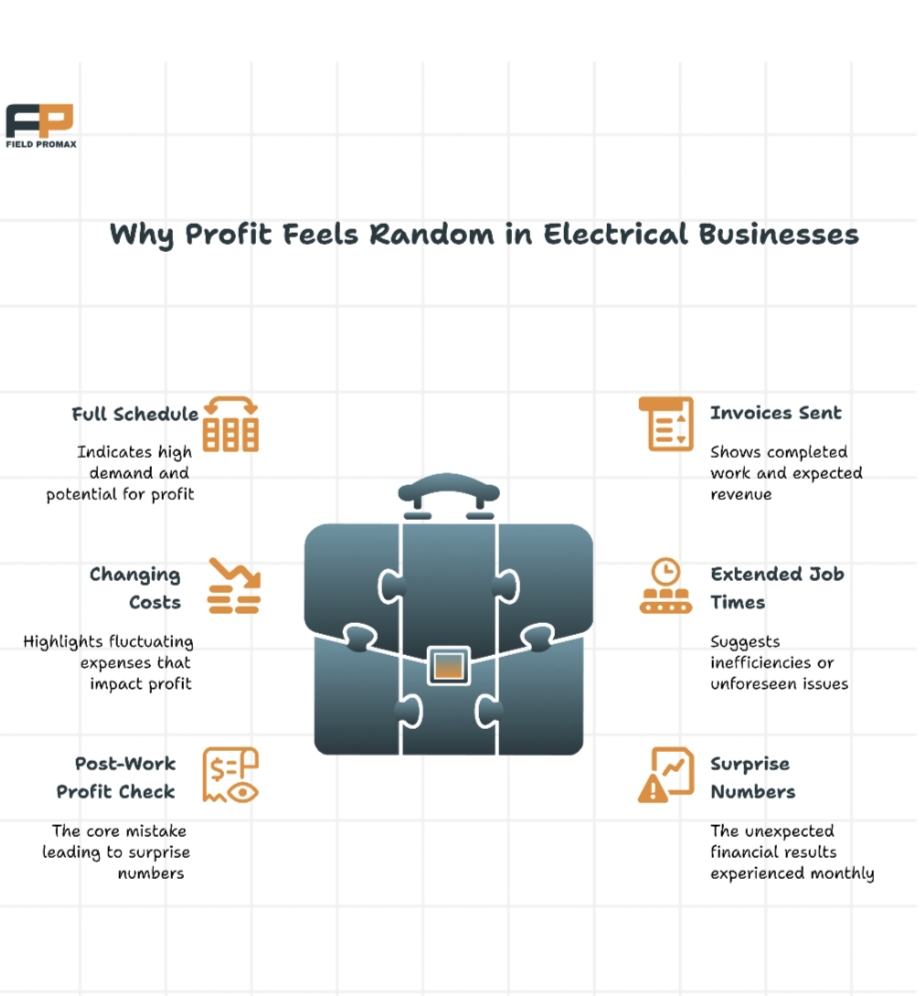

You’re booked solid. The schedule is packed, the vans are rolling, and the phone won’t stop ringing. By all accounts, business is booming. So why does the bank account look a little… thin?

It’s the classic electrical contractor paradox: being busy doesn’t always mean being profitable.

Profit margins rarely vanish in a single, dramatic explosion. They don’t walk out the door in one big theft. Instead, they slip away quietly for five minutes here, a return trip there, a forgotten receipt, or a job that took two hours longer than estimated.

If you don’t track these leaks, you can’t fix them. That’s where job cost tracking comes in. It’s the difference between guessing that you made money and knowing exactly where every penny went.

The Invisible Gap Where Profit Disappears

Running an electrical business is a juggling act. You’ve got materials to order, technicians to dispatch, and clients who want the job done yesterday. In the chaos, it’s easy to look at the big picture of revenue versus total expenses and assume everything is fine if the numbers are black.

But the “big picture” hides a lot of ugly details.

When you don’t track costs on a job-by-job basis, you’re operating on assumptions. You assume the rough-in took eight hours because that’s what you quoted. You assume the materials cost $500 because that’s what you budgeted.

The reality? The rough-in took ten hours because the framers weren’t done. The materials cost $650 because copper prices spiked. That gap between what you thought happened and what actually happened is where your margin goes to die.

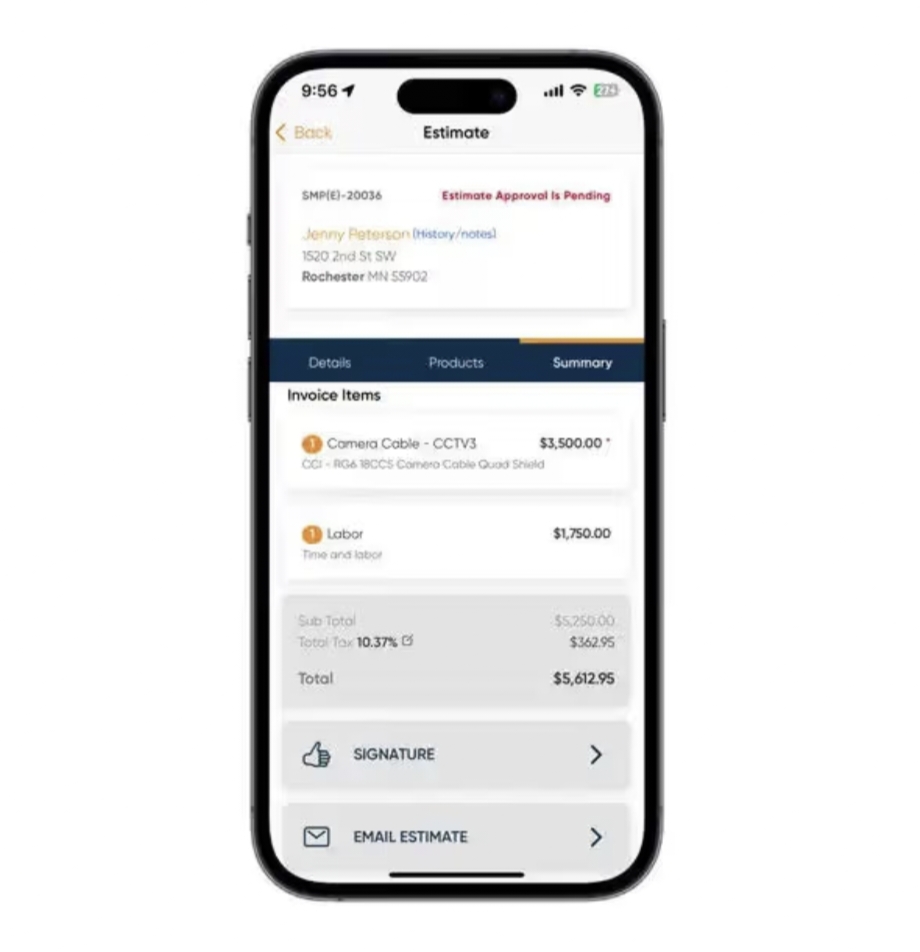

Job cost tracking connects the dots. It forces you to look at:

- The Estimate: What you thought it would cost.

- The Reality: What it actually costs in labor, materials, and overhead.

- The Result: The true profit (or loss) on that specific ticket.

Without this visibility, pricing decisions are just educated guesses. And in a market with rising labor costs and tighter expectations, guessing is a dangerous game.

Labor: The Silent Budget Killer

Let’s talk about labor. It’s your biggest expense and the easiest place to bleed cash.

Imagine you quote a standard service upgrade at eight hours. It’s a job you’ve done a hundred times. But on this specific Tuesday, traffic was a nightmare, the old panel was a rusted mess, and the apprentice spent 45 minutes looking for a tool that was in the truck the whole time.

The job clocks in at ten hours.

You bill the customer the quoted price. The invoice looks clean. The customer is happy. But those two extra hours? You just paid for them. They came straight out of your pocket.

When this happens once, it’s annoying. When it happens across five technicians, three times a week, month after month? You’re talking about thousands of dollars in lost margin that you never even saw leaving.

Without tracking:

- Overtime starts to feel “normal” rather than an exception.

- Estimates never get updated to reflect the reality of how long tasks actually take.

- Payroll eats up cash that should have been profit.

With tracking, these overruns light up like a blown fuse. You see the pattern immediately. You realize, “Hey, every time we send Dave to do a panel upgrade, it takes 10 hours, not 8.” Now you have a choice: train Dave or start quoting 10 hours.

The Trap of “Flat Rate” and Repeat Work

Repeat work like lighting maintenance, inspections, and installs provides consistent income for electrical businesses, but outdated pricing can hurt your profits. Costs like wages, fuel, and compliance have increased, but if your prices haven’t changed in years, you’re likely undercharging.

Tracking job costs helps you stay on top of these changes. By reviewing the average cost of jobs like a “Standard Lighting Upgrade,” you can adjust your pricing to match actual expenses and protect your bottom line.

The Office vs. The Field: Bridging the Disconnect

There’s often a massive wall between the office (where the estimates are built) and the field (where the work happens).

The office builds a quote based on perfect conditions. The technician arrives on site and finds chaos.

Without a feedback loop, the technician might:

- Spend extra time fixing a mess without realizing they’ve blown the budget.

- Do a “quick favor” for the client that isn’t on the work order (and isn’t billable).

- Forgot to document a delay caused by another trade.

Meanwhile, the office is sitting there wondering why the job isn’t profitable, but they have no data to explain it. They just see the hours piling up.

Tools like Field Promax break down this wall. When technicians track time and materials in real-time via a mobile app, that data flows instantly to the office.

- Technicians see the scope clearly.

- The office sees the progress instantly.

- Everyone stays accountable.

It turns a disconnected guessing game into a unified operation.

Why Your P&L Statement is Lying to You

Okay, “lying” is a strong word. But your monthly Profit & Loss (P&L) statement is definitely withholding the truth.

A P&L is a wide-angle lens. It shows you the whole forest. It says, “We made $50k this month and spent $40k.” Great, you made a $10k profit.

But it doesn’t tell you which trees are dead.

Maybe you made $15k on commercial jobs but lost $5k on residential service calls because of travel time. The P&L just shows the net result. You might be celebrating a profitable month while unaware that a specific segment of your business is actively draining your bank account.

Job cost tracking gives you the zoom lens. It ties financial outcomes to operational performance. You can drill down and see:

- Which technicians are the most profitable?

- Which types of jobs have the highest margins?

- Which zip codes are costing us too much in travel?

Many electrical contractors using Field Promax say this visibility changed everything. Seeing job-level data alongside billing made them realize that some of their “best” clients were actually their least profitable ones once all the hidden costs were tallied up.

Moving From Guesswork to Clarity

Implementing job cost tracking isn’t about micromanaging your team or drowning in spreadsheets. It’s about protecting your hard work.

When you make tracking part of your daily rhythm, you stop reacting to bad months and start proactively building good ones.

You begin to:

- Bid Confidently: You know exactly what your break-even point is.

- Spot Issues Early: If a job is going sideways on Tuesday, you can fix it before Friday.

- Scale the Right Things: You stop chasing “busy work” and start chasing “profitable work.”

It’s not about adding complexity. It’s about removing the blindfold.

Stop the Leaks Today

If you’re tired of working hard for thin margins, look at your job costing.

Ask yourself three hard questions:

- Do I know the actual labor cost of the last three jobs we finished?

- Can I easily compare what I estimated versus what actually happened?

- Am I pricing based on today’s data or yesterday’s habits?

You don’t need to be an expert accountant. You just need visibility. Modern platforms like Field Promax make this automatic, connecting your estimates, field activity, and billing in one smooth workflow.

Once you see the leaks, you can plug them. And once you plug them in, that “busy” schedule finally starts to look like a healthy bank account.

Frequently Asked Questions

- What exactly is job cost tracking for electricians?

Think of it as a scoreboard for every single project. It’s the process of recording every dollar spent on a specific job, including labor hours, materials, permits, and subcontractor fees, and comparing that total against what you quoted. It tells you if you actually won or lost on that specific ticket.

- Why do I lose money without it?

Because margin leaks are silent. Without tracking, you don’t notice the extra 30 minutes on-site, the wasted material, or the “scope creep” where a technician does extra work for free. These costs are invisible on a standard invoice but eat away at your bottom line.

- Is this only for big electrical companies?

Absolutely not. Small businesses actually need it more. A large company can absorb a few bad jobs. A small business with tight cash flow can be crippled by them. Job cost tracking helps smaller shops protect every dollar and grow safely.

- How often should I look at these numbers?

Ideally, weekly. Or immediately after a job closes. If you wait until the end of the quarter, it’s too late to fix anything. Real-time tracking allows you to adjust on the fly, fixing a labor overrun before it becomes a financial disaster.