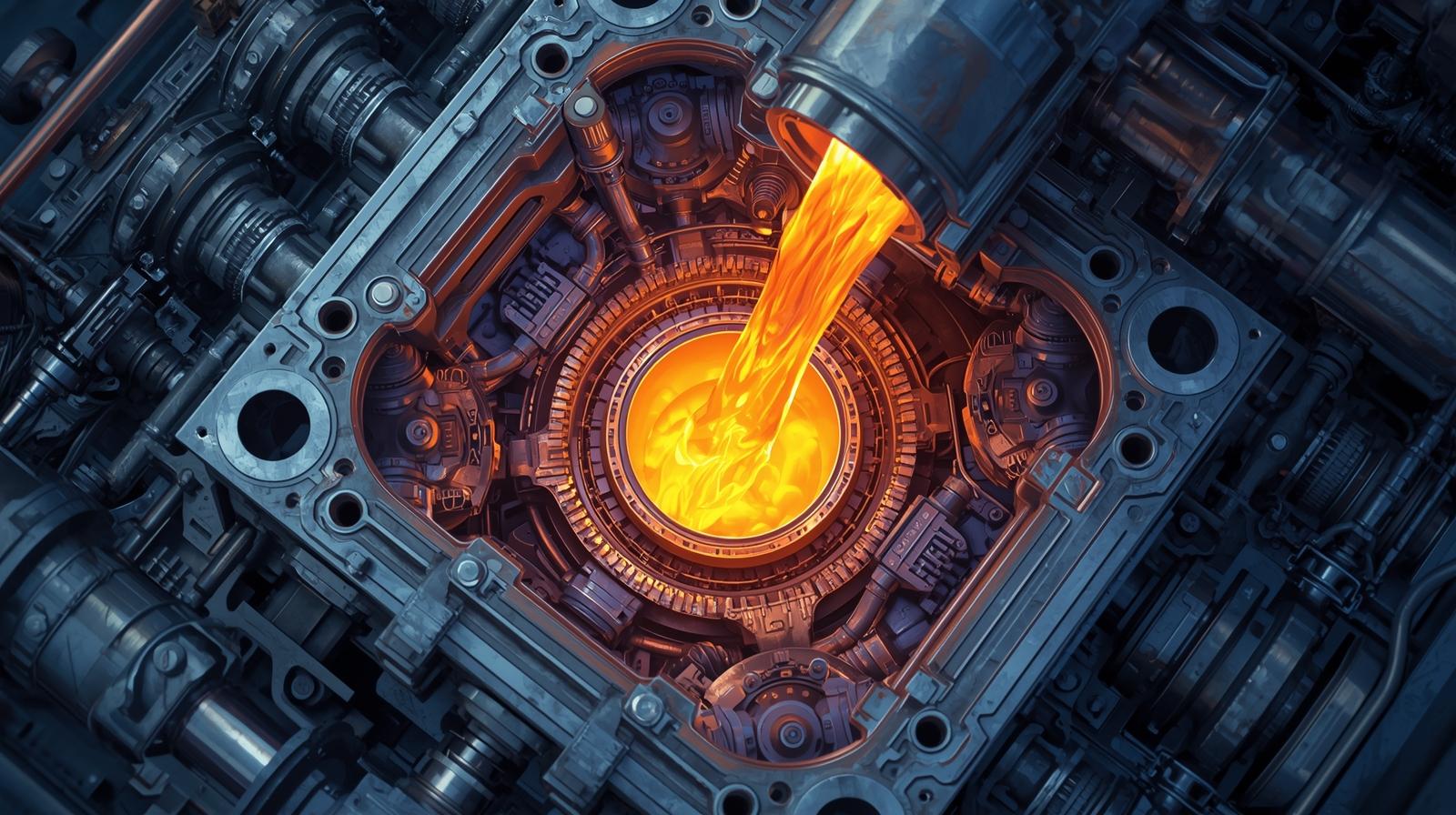

The manufacturing world is constantly evolving, with custom metal casting standing as a central process that caters to a myriad of industries. This technique opens up diverse possibilities for creating complex components with precision, thereby playing a crucial role in sectors ranging from automotive to aerospace.

Understanding Custom Metal Casting

Custom metal casting is a versatile manufacturing process that involves pouring liquid metal into a mould that contains a hollow cavity of the desired shape. The metal is allowed to cool and solidify within the mould, and the cast part is then ejected or broken out to complete the process.

There are numerous casting techniques available such as sand casting, investment casting, and die casting, each offering unique advantages for specific applications. The selection of a method largely depends on the requirements of the project, including the size, shape, and the volume of the components to be produced.

Applications of Custom Metal Casting

Custom metal casting is employed across various industries due to its ability to produce intricate and customised parts. In the automotive industry, it enables the production of parts with complex geometries that are essential for enhancing performance and efficiency. Similarly, in the aerospace sector, casting is used to produce lightweight and durable components that meet stringent safety standards.

The Advantages of Custom Metal Casting

One of the primary benefits of this process is its ability to deliver exceptionally detailed parts, which can significantly reduce the need for post-processing and finishing. Additionally, custom metal casting is highly efficient, offering the ability to produce multiple copies of parts quickly, which is particularly beneficial for high-volume production.

Choosing the Right Casting Method

The selection of the appropriate casting method is crucial to achieving the desired results. Sand casting, for example, is often used for producing large metal parts, whereas investment casting is suited for more intricate designs. Die casting, known for its speed and high-volume capability, is ideal for mass production of smaller components.

Material Selection in Metal Casting

The choice of material is another critical factor in custom metal casting. The decision is typically guided by the intended application of the cast part. Common materials used include aluminium, which is favoured for its lightweight and corrosion-resistant properties, and steel, known for its strength and durability.

Implementing Innovative Solutions

Innovation in metal casting is pivotal in addressing the growing demands for complex and precise components. Advances in technology, such as 3D printing in creating moulds, have enhanced the efficiency and capabilities of custom metal casting techniques. These developments not only improve the quality and complexity of the parts produced but also reduce costs and lead times.

The Role of Quality Control

Quality control is a significant aspect of custom metal casting, ensuring that the components meet the required standards and specifications. This involves rigorous testing and inspection processes to identify any inaccuracies or defects in the cast products. Techniques such as radiographic and ultrasonic testing are commonly employed to ensure integrity and compliance.

Cost Considerations

While custom metal casting offers numerous benefits, it is important to understand the cost implications associated with this manufacturing process. The costs are mainly influenced by the complexity of the design, the type of metal used, and the volume of production. However, despite the initial investment, the process can be cost-effective in the long run by minimizing waste and reducing material usage.

Environmental Impact

The environmental impact of custom metal casting is an area of growing concern. The industry is taking strides towards more sustainable practices by implementing recycling and waste reduction initiatives. The development of eco-friendly materials and energy-efficient processes are some measures being adopted to diminish the ecological footprint of metal casting.

Future of Custom Metal Casting

The future of custom metal casting appears promising, with continuous advancements that are set to revolutionize the industry. Innovations such as automation and the integration of artificial intelligence in production processes are poised to enhance precision, efficiency, and flexibility in casting operations.

Conclusion

In conclusion, custom metal casting remains an indispensable process in modern manufacturing. By embracing innovative solutions, industries can harness the full potential of this technique, paving the way for advancements that meet the ever-evolving demands for precision and complexity in manufacturing. As the industry continues to evolve, stakeholders must remain committed to sustainable practices and technological innovation to drive future growth and success.